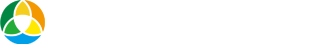

Advancing the potential of our power plants within the framework

of the “Three Points of Safety”

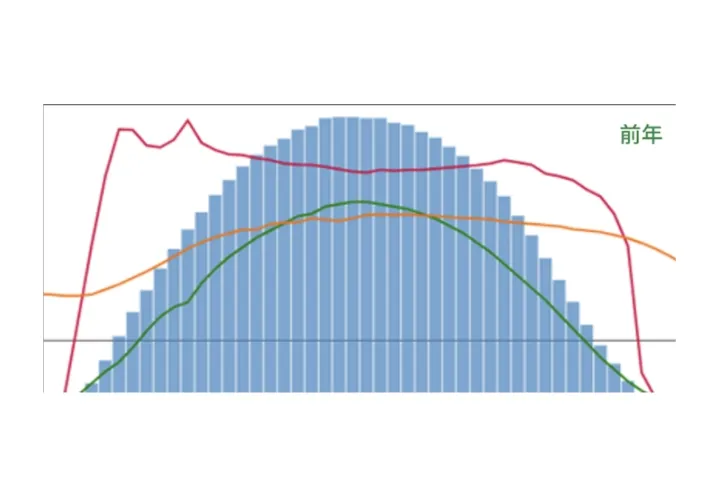

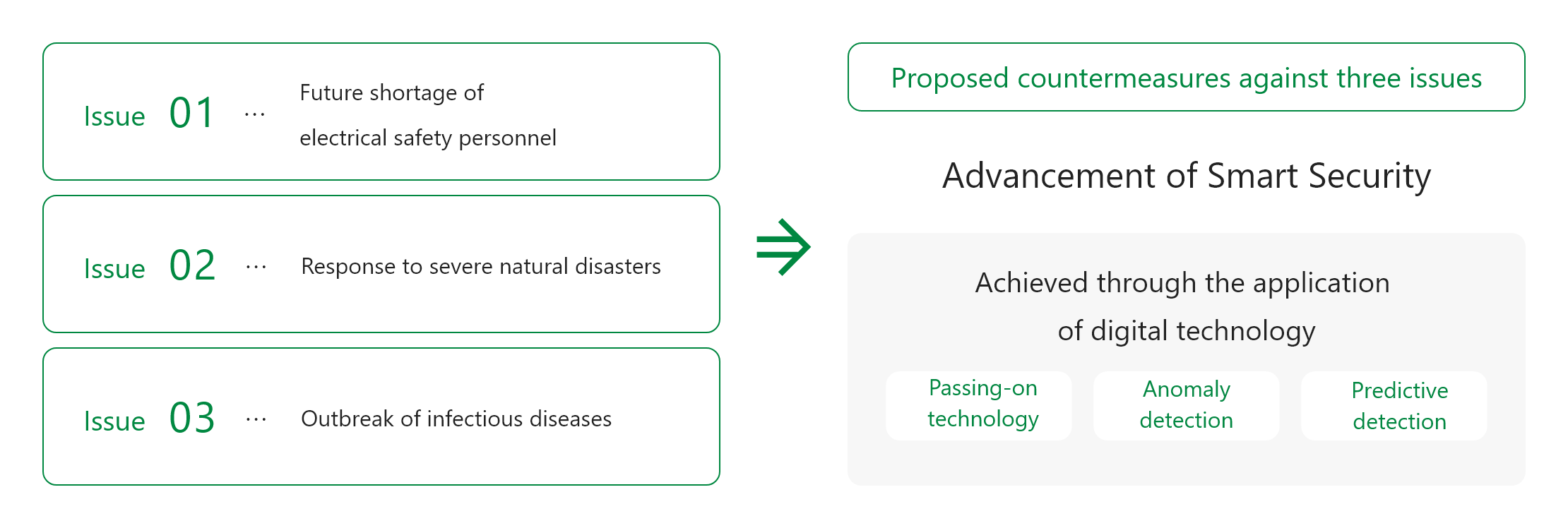

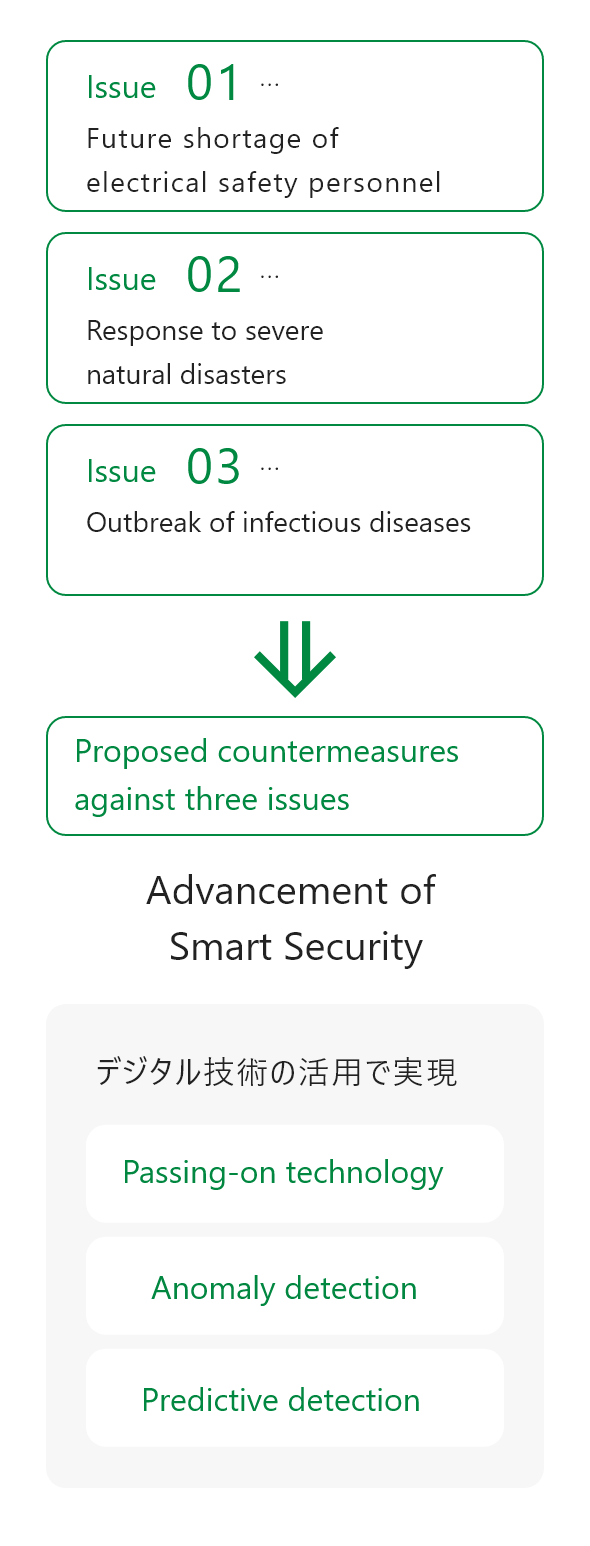

Japan Green Power Development Corporation of Japan (GPD) is currently launching a number of new projects, including biomass research, an energy storage plant initiative, and SAF research. We will continue to foster all kinds of businesses to realize “local production for local consumption of electricity,” as laid out in our Island Power Generation® plan. These endeavors extend beyond our company, signaling the expansion of Japan’s energy sector and the rising trend in outsourcing facility maintenance.

As we anticipate this future, we will persist in enhancing our proficiency in facility maintenance and operations. All the while, we will strive to ensure the stable progress of our operations, keeping in mind the Three Points of Safety; safety of employees, safety of the neighborhood, and safety of power plants. We believe this approach will contribute to the advancement of our enterprise and the broader energy industry in Japan.